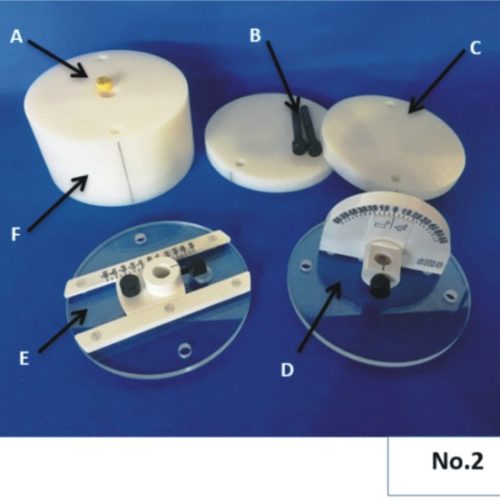

Parts:

A. Graduated support for the maintenance of the measurement geometry and the source-probe distance.

B. Screw for fixing the different measuring distances.

C. Graduated support for fixed part, according to the diameter of the probe.

D. Disk for location and measurement of point source.

E. Graduated supports for different probe diameters.

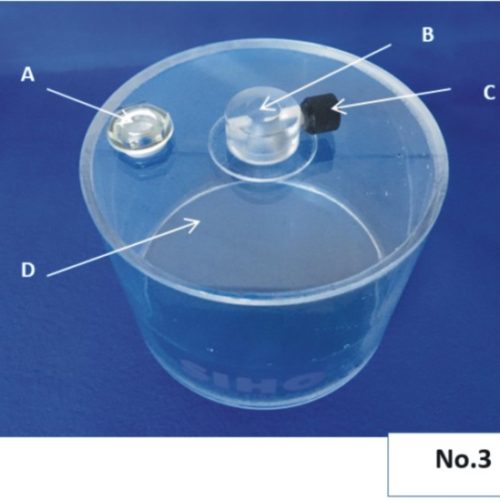

For air tests:

- Air sensitivity

- Sensitivity through lateral air shielding

Description: The probe is located with the corresponding device in C, adjusting with the screw F and measurements are made in air for 0, 1, 3 and 5 cm. In the case of test 2, the piece of C is rotated 90 ° from the horizontal position, carefully holding and moving the pin G just upwards, to the hole in the left front edge of the support.

NOTE:

Handle each piece with care, without forcing it and when using unfinished liquid finite source locate it in the same 5mm hole, without spilling and do not see it.

ONLY MANIPULATE BY TRAINED PROFESSIONALS